Investment Castings

Ecrimesa Group manufactures steel and aluminum parts by investment casting. It was originally founded in 1964 in the northern Spanish city of Santander and has remained operating from this location ever since.

With a staff of over 250 workers, Ecrimesa combines youth and experience to obtain a dynamic and modern company. Its fundamental objectives are to care for the service to the client and to care for the environment. To achieve this, Ecrimesa has state of the art equipment.

Ecrimesa has a mold manufacturing workshop equipped with modern machinery such as wire-erosion machines or 5 axis high-speed machining centers. Also, its technical department is equipped with the most modern design systems (3D CAD-CAM Pro Engineer and Hypermill). Its technical staff has extensive experience in the use of these software packages.

The wax workshop is highly versatile, by combining automatic, semi-automatic, and manual injecting machines. It can meet all the different requirements of the customers. The facilities are also equipped with an automatic de-waxing installation for the removal of soluble wax cores. Also, the pre-produced ceramic core technology is widely used in the wax injection process.

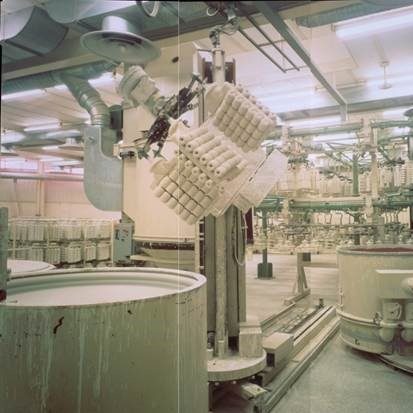

The shell production process is automated, having two robotic production lines. These lines operate in strict conditions of temperature and humidity, controlled by modern air-conditioning systems. These two installations yield a large production capacity and flexibility.

The melting department is equipped with two sets of variable frequency induction furnaces (a total of 5 furnaces) which yield more than 12000 Kg of molten steel per day. Moreover, this production is achieved with a level of quality that is highly regarded by its customers. Samples are sent via a pneumatic line to the metallurgical lab which can then analyze and certify each melt in a few seconds.

A wide range of heat treatments is offered as a complement to the cast component. These are performed either in close-working subcontracted companies or in the in-house installations. Moreover, depending on the needs and requirements of the customer there is a modern automatic installation for pickling and passivation available in the facilities.

In an endeavor to provide full service to customers, Ecrimesa can offer a range of subcontracted services performed by either domestic or European companies: Fast prototyping, machining operations, surface treatments, heat treatments, and sub-assemblies among others.